Ad Code

Translate

Five Do’s For a Healthy Turnover That Bolsters Talent-Retention

October 20, 2025

Smart strategies for trading on crypto exchanges

October 20, 2025

What is Ozempic (semaglutide)? (Updated in 2025)

January 30, 2025

Discover Honeybee Pharmacy (2025 Guide Important Consumer Tips)

October 14, 2025

Posture Bra: Improving Back Support and Comfort

October 20, 2025

How To Find Suitable Properties In Cyprus?

October 20, 2025

10 Effective Strategies to Improve Domain Authority of Your Website

October 20, 2025

Choosing the Right Industrial Robot for your Factory

Khabza Mkhize

January 23, 2023

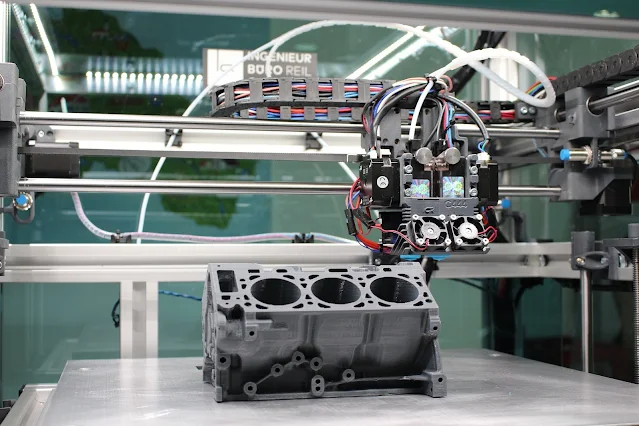

Various industrial robots in use today have made their name in the manufacturing circles, like the EVS CNC robot, have transformed how assembly plants run their day-to-day operations, with most of the plants that switch to these types of robots starting to see their profits gradually rise. With robots forming a massive chunk of factory labour, it is paramount that you only work with the best; after all, the whole point of replacing human labour with robots is to improve productivity. So how do you go about choosing a robot for your factory?

The Payload

|

| Source: https://www.evsint.com/ |

The Number of Axes

|

| Source: https://www.pinterest.com/ |

The Reach

Industrial robots depend on their arms to do all their operations. These arms come with grippers that enable them to take hold of the most minor things. Robots with longer arms are suitable for packaging as they can easily pick items from afar without moving. Shorter robotic arms are ideal for intricate work, like assembling computer processors that require minimal movements. When choosing a robot, consider its arm reach first to ensure it aligns with the task you have in mind.Speed and Accuracy

|

| Source: https://pixabay.com/ |

Program Complexity

The best industrial robots are not just for show; they are run by some of the most complex programs ever devised by man. The advantage of using such a robot is that you are assured of the utmost accuracy with the most minuscule margins of error. The downside ofis that it will require qualified experts to run them. Therefore, when getting a robot for your plant, go for what your technician needs in case of a malfunction. The last thing you want is to stop the product so you can send the robot back to the manufacturers for repairs.Body Weight

|

| Source: https://www.pinterest.com |

Protection Level

The protection level is a very vital aspect of owning industrial robots. They first have to be safe to work around since some functions need human input. They should have an easy-to-access overriding button that can be switched off immediately in case of an accident. Protection from the kind of work the robots do is also vital. For instance, if the robot handles many flammable materials or acids, it should be well protected by a particular casing to avoid accidents and damage during work.Conclusion

Technology can move forward whether people want it to or not. It is only a matter of time before every factory fully automates. As much as this will cause disruptions in the job market, there is very little that can be done to stop it. On a positive note, robots are programmed to give their everything, which means that the quality of products and services will continue increasing every day, which is something worth looking forward to.Featured Post

DL Mining Launches Ethereum Contract Participation Service, Helping Users Earn $2K Stable Daily Returns

Zizo Gala-Mkhize-

October 20, 2025

Soapie Teasers

Sister Sites

Most Popular

List of 6,000+ Dofollow Commentluv Blogs FREE (Updated 2025)

January 16, 2025

Five Do’s For a Healthy Turnover That Bolsters Talent-Retention

October 20, 2025

What is Ozempic (semaglutide)? (Updated in 2025)

January 30, 2025

Popular posts

List of 6,000+ Dofollow Commentluv Blogs FREE (Updated 2025)

January 16, 2025

A Wood-Burning Stove in a Tent: A Guide to Safe Hot Tenting

April 08, 2021

Five Do’s For a Healthy Turnover That Bolsters Talent-Retention

October 20, 2025

Footer Menu Widget

Created By Blogspot Theme | Distributed By Gooyaabi Templates

Social Plugin