Ad Code

Translate

Smart strategies for trading on crypto exchanges

October 20, 2025

Five Do’s For a Healthy Turnover That Bolsters Talent-Retention

October 20, 2025

Discover Honeybee Pharmacy (2025 Guide Important Consumer Tips)

October 14, 2025

What is Ozempic (semaglutide)? (Updated in 2025)

January 30, 2025

Posture Bra: Improving Back Support and Comfort

October 20, 2025

How To Find Suitable Properties In Cyprus?

October 20, 2025

10 Effective Strategies to Improve Domain Authority of Your Website

October 20, 2025

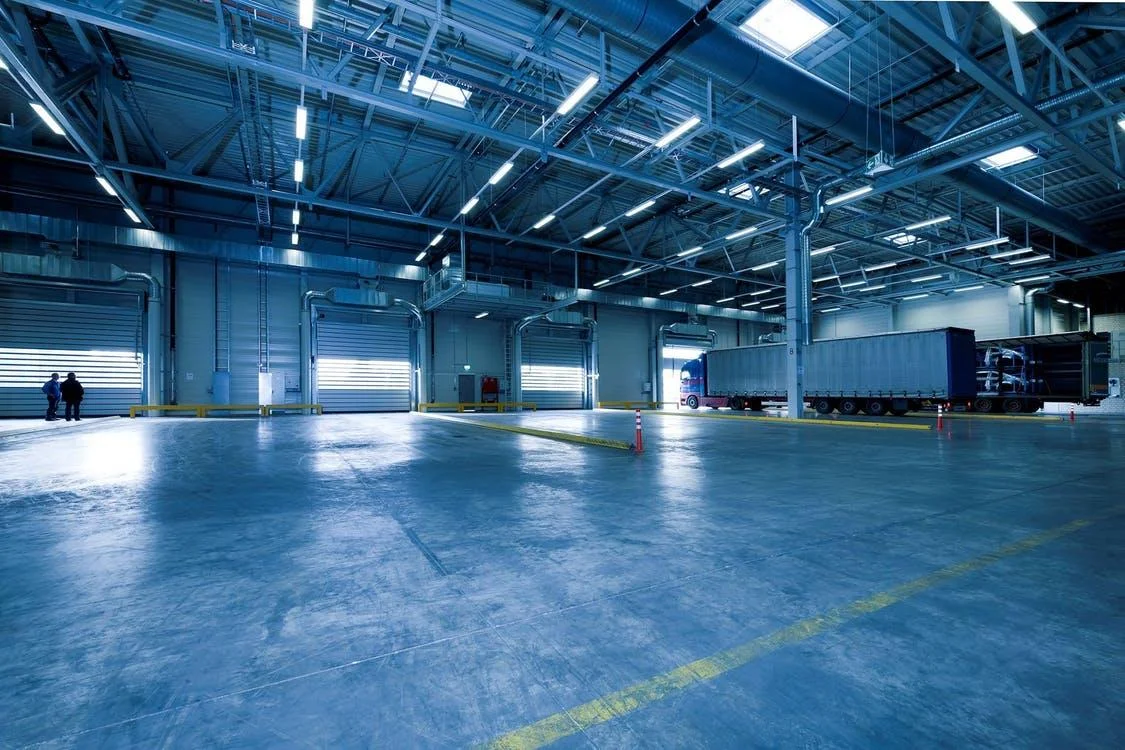

5 Awesome tips to best utilize warehouses for small businesses

Khabza Mkhize

October 23, 2019

Warehousing

Warehousing involves keeping finished products or goods until they are distributed or sold at a later point in time. In the initial stages, a small business may be using a spare room, garage, or a basement for storing products; however, with the increase in production, the need for a proper warehouse becomes acute.Warehousing is a vast topic, and with the exponential rise in the retail business over the past few years, storage facilities have become one of the most pressing problems for businesses.

While big businesses have the available funds and resources at their disposal, which can be used to rent or purchase large areas and customize it as per their business demands. Small or medium enterprises, on the other hand, do not have that kind of money. They need to carry out their warehousing operations within limited space and resources.

The article below will discuss a few tips that will enable them to utilize their warehouses to the maximum.

Tips to best utilize warehouse for small businesses

For small businesses, warehousing starts with the very first step: cleaning of the premises, and overhauling it. Next comes proper maintenance.Rather than getting afraid of this task, business owners should note that warehousing is simply about using your common sense.

It is not imperative to follow these tips in their sequence. These will only provide you with an overall idea regarding how you should professionally operate your warehouse.

Assess and Improvise the Floor plan of the warehouse

When you enter any premises for the initial inspection, the first thing you should consider is the floor plan. You should see the floor plan even before leasing or renting the property.Ideally, all the required furniture and equipment like shelves, tables, and benches must be placed within the premises in a logical order so that the staff working in the warehouse does not find difficulties.

The layout should be such that it should help the staff in their work not hinder them.

The best layout plan for a warehouse

A perfect layout plant for an operational warehouse enables easy availability of goods at all times. It should offer the maximum utility of space, and also provide working space to the employees.The layout plan for your intended warehouse should incorporate all the above. Another aspect is the nature of your small business, and the type of goods you intend to store in the warehouse.

Take a walk around the premises, and try to envision how you can increase the ease and efficiency of your warehouse while remaining within the confines of the premises

Working areas of the warehouse

- It is better to have a warehouse that houses separate areas for receiving goods, packing, and deliveries.

- All these areas should be marked clearly in the warehouse layout plan.

- There must also be an office space for carrying out the required paperwork.

Safety

The safety of the employees and your product is one of the most critical aspects of the warehouse. Sometimes, a warehouse contains heavy machinery and equipment for moving products. Sometimes even the most skilled forklift drivers will not be able to avoid warehouse accidents if it is not well maintained. That is why regular warehouse maintenance should be of top priority so that you have a safe work environment.There must be ample room available in the warehouse where these machines can move and maneuver without posing any risk to the employees.

Installation of fixtures

The primary purpose of the warehouse if to store your products until they are delivered. These products will not be scattered all over the place.You need to install appropriate fixtures in the warehouse for keeping your products safe and always within reach.

Shelves and racks should be appropriately selected. And so is the durability depending upon the nature of products that have to place on them prior delivery. You can also utilize vertical space within your warehouse for maximum yield.

Getting to know your product

Warehousing requires that you know the nature of your product, and how you should store those products in a manner which makes it easier for you to keep it and retrieve it with maximum ease.The requirements of a manufacturing unit are entirely different from that of simple trading functions.

In some cases, you will need to store raw material for onward delivery to the manufacturing department. These should be kept handy. Some products have specific storage requirements. These could include temperature control and fragility.

Your house should cater to all these general as well as specific storage requirements.

Organize your products in the warehouse

Stacking and organizing the products within warehouse premises is one of the most important aspects of carrying out efficient business operations.The products that are fast running should be within easy reach of the staff, and the ones not in demand with a higher frequency should be stored inside.

The employee should not have to go inside the warehouse for fetching the same thing ten times a day. Such things should be kept in the front so that warehouse personnel can see it and bring it immediately.

The dead stock should not be placed in front where everybody can get a glimpse of it. If it remains there for a more extended period, occupying the space could have adverse effects. The order fulfilment should never take much time because the supply chain will always depend on your warehousing operations.

Proper Labeling

Proper labeling is one of the critical aspects of warehousing. Since most of the products are in similar cartons and cases, after a while, even the most experienced person working in the warehouse starts to forget which product is in which box.You need to label everything in your warehouse, from individual items to work areas, clearance heights, maximum capacity, and safety hazards.

If you have correctly labeled everything, and also logged them successfully in the register, it will increase your working efficiency manifold.

The Final Word

As discussed above, warehousing is the backbone of any business, whether it is a retail outlet, a manufacturing unit, or a single trading entity. The tips provided in the above article should serve only as of the tip of the iceberg. The actual warehousing operation requires lots of planning and efficient execution of those plans.

It is not sufficient to establish and operate a warehouse efficiently. Regular maintenance of the premises and continuous improvement in functions is also a requirement.

As your business starts to grow, you will need to make adjustments in your warehousing functions. With the introduction of new products, you will be required to make space adjustments.

Warehousing functions will continue to evolve with time.

Featured Post

DL Mining Launches Ethereum Contract Participation Service, Helping Users Earn $2K Stable Daily Returns

Zizo Gala-Mkhize-

October 20, 2025

Soapie Teasers

Sister Sites

Most Popular

List of 6,000+ Dofollow Commentluv Blogs FREE (Updated 2025)

January 16, 2025

Five Do’s For a Healthy Turnover That Bolsters Talent-Retention

October 20, 2025

What is Ozempic (semaglutide)? (Updated in 2025)

January 30, 2025

Popular posts

List of 6,000+ Dofollow Commentluv Blogs FREE (Updated 2025)

January 16, 2025

Five Do’s For a Healthy Turnover That Bolsters Talent-Retention

October 20, 2025

What is Ozempic (semaglutide)? (Updated in 2025)

January 30, 2025

Footer Menu Widget

Created By Blogspot Theme | Distributed By Gooyaabi Templates

Social Plugin