Ad Code

Translate

Five Do’s For a Healthy Turnover That Bolsters Talent-Retention

October 20, 2025

Smart strategies for trading on crypto exchanges

October 20, 2025

What is Ozempic (semaglutide)? (Updated in 2025)

January 30, 2025

Discover Honeybee Pharmacy (2025 Guide Important Consumer Tips)

October 14, 2025

Posture Bra: Improving Back Support and Comfort

October 20, 2025

How To Find Suitable Properties In Cyprus?

October 20, 2025

10 Effective Strategies to Improve Domain Authority of Your Website

October 20, 2025

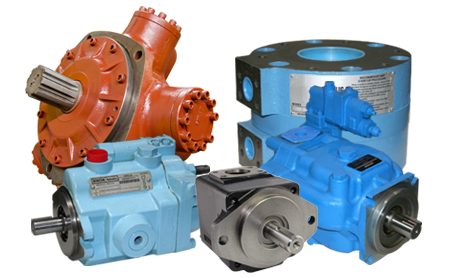

Hydraulic pump and motor repair from dynamic pumps

Khabza Mkhize

February 04, 2024

Hydraulic machines are liquid fluids used to operate tasks and emerging operations for construction purposes, and automobiles are the most common example of hydraulic machines. In this type of machine, hydraulic fluid or oil is pumped into various hydraulic motors and hydraulic cylinders in the machine system to create pressure and prevent current resistance. The plant can be controlled automatically by control valves and distributed through houses, pipes, and tubes.

Why repair and maintenance are required?

- Proper working: It has been said that small costs can prevent considerable damages, and in the field of Engineering, you can see this phrase is accurate. Engineers can only suffer if proper measures are taken to operate hydraulic machines. So it would be better to put some amount on hydraulic machines such as hydraulic motor hydraulic pumps for their adequate working regularly.

- To avoid big happenings: Engineering is where you must take complete care while operating machines that can hurt any human being or your project. Suppose proper maintenance and repair measures are taken on time. In that case, it can turn into big problems and significant happenings in the future, so it is better to put some amount regularly to avoid the happenings.

- To avoid expenses: Hydraulic Machines such as hydraulic pumps and Hydraulic Motors can turn into expenses if you don't repair and maintain the requirements needed by hydraulic Machines; it would be better to put a small amount regularly rather than having significant costs after a couple of years.

- Quality impact: If proper care and take are not taken, it will be a significant loss to hydraulic operators as the quality output will not be possible. It can become a big problem in the future as the small quality impact can become significant losses if proper maintenance isn't taken.

- Production impact: Hydraulic Machines such as hydraulic pumps and Hydraulic Motors in the engineering field is most important tools that can be used by engineers to solve many engineering problems, most of the work done in this field depends on those tools and techniques that had been used by daily operations. If the machinery is repaired and proper repair and maintenance are done, it can become a massive problem for engineers.

Hydraulic pumps and hydraulic motor repair services

It has been seen that hydraulic machines have stopped suddenly working; there may be several reasons for sudden happenings with hydraulic machines. But here, dynamic pump services let you work on those machines efficiently temporarily, as they can be replaced by dynamic pumps. What dyna, dynamics services of comprehensive machines that can be replaced for a temporary show that normal working wouldn't affect.This is a common sign that the hydraulic pump needs repairing.

- Unnecessary loud noise: When Hydraulic Machines and pumps make unnecessary sudden loud noises, what is the sign that they need repair maintenance. It would be better to replace dynamic machines with those machines temporarily.

- Inside leakages: if pumps leak outside and inside, it is a sign that the machine needs to be repaired.

- High temperature: If hydraulic machines such as hydraulic pumps and motors work at high temperatures, it is a sign that hydraulic machines must be repaired. Overheating can cause significant damage to the machine.

Featured Post

DL Mining Launches Ethereum Contract Participation Service, Helping Users Earn $2K Stable Daily Returns

Zizo Gala-Mkhize-

October 20, 2025

Soapie Teasers

Sister Sites

Most Popular

List of 6,000+ Dofollow Commentluv Blogs FREE (Updated 2025)

January 16, 2025

A Wood-Burning Stove in a Tent: A Guide to Safe Hot Tenting

April 08, 2021

Five Do’s For a Healthy Turnover That Bolsters Talent-Retention

October 20, 2025

Popular posts

List of 6,000+ Dofollow Commentluv Blogs FREE (Updated 2025)

January 16, 2025

What is Ozempic (semaglutide)? (Updated in 2025)

January 30, 2025

A Wood-Burning Stove in a Tent: A Guide to Safe Hot Tenting

April 08, 2021

Footer Menu Widget

Created By Blogspot Theme | Distributed By Gooyaabi Templates

Social Plugin