Ad Code

Translate

Smart strategies for trading on crypto exchanges

October 20, 2025

Five Do’s For a Healthy Turnover That Bolsters Talent-Retention

October 20, 2025

Discover Honeybee Pharmacy (2025 Guide Important Consumer Tips)

October 14, 2025

What is Ozempic (semaglutide)? (Updated in 2025)

January 30, 2025

Posture Bra: Improving Back Support and Comfort

October 20, 2025

How To Find Suitable Properties In Cyprus?

October 20, 2025

10 Effective Strategies to Improve Domain Authority of Your Website

October 20, 2025

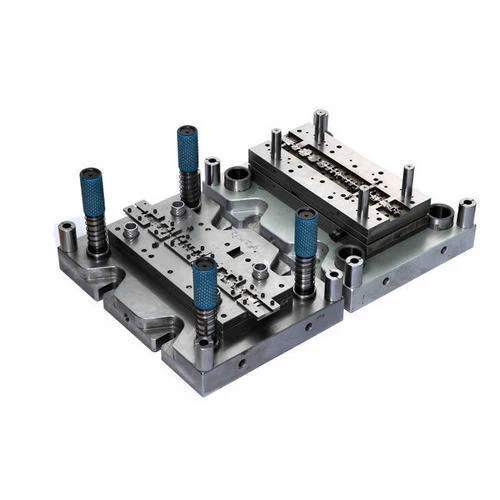

The Functionality Involves In Stamping Dies

Khabza Mkhize

February 04, 2024

The expression “stamping dies” is a general term for the tooling used to produce stamped parts. A stamping die set consists of male and female components that oppose both forms and punch holes in the metal.

Stamping dies are the devices used in stamping machines. Each stamping machine can have one or more Stamping dies, depending on its type and work. Stamping dies are the critical components in stamping machines that do the actual punching, casting, cutting, and shaping of the metal sheet.

The birth of Stamping dies.

Stamping is the process used to cut and form the metal sheet into a required contour with the help of a tool known as a stamping die. Custom sheet metal components are used widely, from your desktop to aircraft; all are manufactured using Stamping dies. The preliminary phase in the stamping tool and die making is stamping die design, which is carried out as soon as the component design is completed. This initial step of the drawing stage of the Stamping die is exceptionally crucial because only a good quality stamping die blueprint can produce perfect stamped components that are durable and require less maintenance.

Press tool die design necessitates selecting manufacturing processes, desired metal stamping operations, basic strip layout, type of stamping presses, etc. A good tool designer thoroughly knows these elements to construct a perfect press tool die design. In the past decade, computer-aided design techniques have been developed to assist Stamping die designers.

A design for accurate production

Various functionalities are involved in press tool die designs essential for accurate production. The first stage in the Stamping die design is evaluating the part to be made, its dimensions, properties, and the complexity of the form. Next, the designer will carry on with the strip layout design,, finalize the cutting force and stamping die-set to be used,, and then start making the assembly sketch. After that, drawing of die parts, part details, and the final step of preparation of the bill of materials is undertaken.

Fundamental operations of Stamping die.

The bare die operations are shearing, drawing, and bending. In Stamping, the metal sheets are placed in a press tool with a cavity mainly designed to give the metal sheet the preferred shape. The upper part of the Stamping die connects to the press slide, while the lower part connects to the press bed. Stamping dies have many kinds, such as single-station, compound, progressive, multiple-station, and tandem press lines.

Stamping could be placed in metal panels or as a series of presses in a press line. Stamping dies, and presses can possess different input variables based on press parallelism, tonnage, shut height, counterbalance pressure, and media speed. The same stamping press can be reused by replacing one die with another. The placement of Stamping dies is known as die setup. The number of parts produced in a die setup is called a batch.

Types of stamping die.

The most common types of Stamping die to perform cutting and forming operations. Cutting dies are used to shear sheet material. Punching is an additional function of cutting dies. Punching removes a slug from the sheet metal stock to produce a slot or hole. The forming operations accomplished by stamping dies are drawing, bending, flanging, and hemming.

Multiple operations could be performed within a single stamping die or at several Stamping die stations within a die set with a single press stroke. Single-station stamping can be either combination dies or compound dies. Multiple-station dies are arranged to accomplish a series of sequential operations.

The design of press tool dies is not just an art but also a science. It plays an essential role in our daily lives.

Featured Post

DL Mining Launches Ethereum Contract Participation Service, Helping Users Earn $2K Stable Daily Returns

Zizo Gala-Mkhize-

October 20, 2025

Soapie Teasers

Sister Sites

Most Popular

List of 6,000+ Dofollow Commentluv Blogs FREE (Updated 2025)

January 16, 2025

Five Do’s For a Healthy Turnover That Bolsters Talent-Retention

October 20, 2025

What is Ozempic (semaglutide)? (Updated in 2025)

January 30, 2025

Popular posts

List of 6,000+ Dofollow Commentluv Blogs FREE (Updated 2025)

January 16, 2025

Five Do’s For a Healthy Turnover That Bolsters Talent-Retention

October 20, 2025

What is Ozempic (semaglutide)? (Updated in 2025)

January 30, 2025

Footer Menu Widget

Created By Blogspot Theme | Distributed By Gooyaabi Templates

Social Plugin